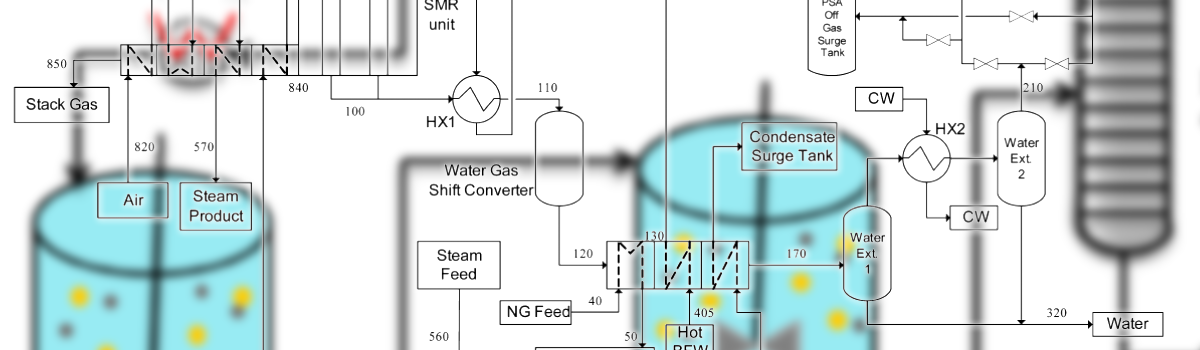

This site provides an array of information associated with our research and teaching in the areas of computer-aided process analysis, simulation, design, and control. It presents information describing our graduate students, collaborations and academic guests, teaching activities, research activities, publications, and computing hardware.

Our facilities are located in Rooms 372 and 316 of the Towne Building.

Warren D. Seider

Warren D. Seider

Professor

Dept. of Chemical and Biomolecular Engineering

University of Pennsylvania

Philadelphia, PA 19104-6393

Phone: 215-898-7953

email: seider@seas.upenn.edu