QNF Critical Point Dryer Wet Chemical Procedure

This describes the sequence of wet chemical processing steps required for the use of the critical point dryer.

- If you are using hydrofluoric acid (HF) or buffered oxide etch (BOE, a mixture of HF and ammonium fluoride) for your release process start with Section 1.

- If you are using anything else, please rinse your samples sufficiently so that they end up in de-ionized water and skip to Section 2.

Section 1: Rinse Procedure

This process starts with a wet etch using either HF or BOE. Both of these chemicals are purchased directly from a vendor. This work is performed in the dedicated HF bench located in Bay 3, Wet Processing, of the clean room. While working at the HF bench, appropriate HF personal protective equipment (PPE) must be worn.

Put on an apron.

Put on a face shield and make sure it fits properly.

Put on green nitrile gloves for HF Bench.

Rinse procedure

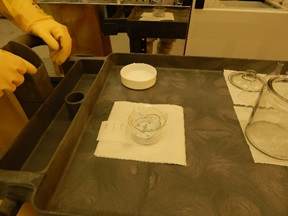

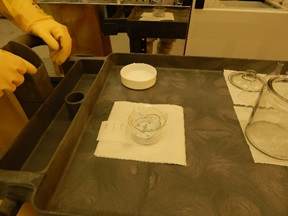

- The user will be mounting their samples in an appropriately sized basket provided by Tousimis, the manufacturer of the critical point dryer.

- Once this etch with HF is complete, the user will transfer the basket containing their sample(s) to a container of deionized water.

- The water rinsing step will require a minimum of two containers of DI water.

- The basket and samples will be allowed to soak in each successive bath of DI water for a minimum of 3 minutes and will involve at least 4 water baths, with the DI water in each dish being disposed of and replaced with fresh DI each cycle.

- The last of these rinse steps should occur in a glass container having a lid that can be secured and this closed container will be transferred to a wheeled cart that sits between the critical pint dryer and the HF bench.

- The purpose of this rinse sequence is to eliminate any HF from the samples and to keep them wet.

Perform wet release with HF or BOE in HF Bench

Section 2: Transfer the samples into methanol

- Once the samples have gone through sufficient rinsing in DI water, they need to be transferred to the solvent bench in Bay 3.

- This transfer will use a sealed container placed on a wheeled cart, to avoid spills, as it is critical that the samples not be allowed to dry during these wet processing steps.

- The user will wear all appropriate PPE for working at the solvent bench.

After final rinse, transfer container with cover, and

label onto lab wipes on the top of the wheeled cart.

Return green gloves and get tan gloves for solvent

bench work.

Transfer the samples into methanol

- In the solvent bench, the basket and sample(s) will be transferred between two dishes of methanol following the same protocol used in the rinsing that follows the HF etch step.

- The final methanol bath will be in a similar container to that used to transfer the basket and sample(s) from the HF bench to the solvent bench.

- Once complete, the basket and sample(s) will be transferred to the critical point dryer in a closed container placed on a wheeled cart to avoid spills.

Roll wheeled cart over to solvent bench, and perform

sample rinse and from de-ionized water to ultra-pure

methanol from glass bottle in glass beakers.

Once finished, transfer covered container and label

to wheeled cart.

While at the solvent bench, the user will pre-pour, into the clearly marked glass transfer bottle, the volume of methanol necessary to pre-fill the process chamber, as determined for the respective sample basket being used.

Pour maximum of 250 mL of methanol from glass

stock bottle in wide mouth brown glass transfer

bottle using the glass funnel provided.

This methanol transfer bottle will also be placed on the wheeled cart for transfer to the CPD.

Place this small “transfer” bottle of methanol onto

the wheeled cart.

Bring the samples to CPD and change PPE

- Roll the wheeled cart to the critical point dryer.

- Take off the tan gloves and return them to the table.

- Take off the face shield and hang it on the rack.

- Take off the apron and hang it on a hanger.

- The only Personal Protective Equipment (PPE) required at the critical point dryer is a face shield while you are pouring the methanol.

- Once the chamber lid is secure, the face shield can be returned to the rack.

Section 3: Fill methanol in the process chamber

The process chamber of the critical point dryer needs to be prefilled with methanol. The volume of methanol required is that which is deep enough to just cover the samples with a maximum fill depth indicated by the upper hole in the side of the chamber. After the methanol is poured into the chamber, the basket and sample(s) are then transferred into the process chamber and the chamber lid is secured. At this point, a predetermined process sequence is run on the critical point dryer. This sequence cools the process chamber, introduces liquid carbon dioxide (CO2) into the chamber to displace the methanol (involves elevated pressures), the chamber is then heated to transition the CO2 from liquid to gas above the critical point which happens with no surface tension, and then the excess pressure is vented thereby returning the chamber to atmospheric pressure and the samples are removed from the system.

Section 4:

PPE required at the critical point dryer consists of needing to wear a face shield while methanol is being poured into the process chamber.