Technics Recipes

Updated on 10/14/2014

Contents

1 Oxygen plasma etching(cleaning) condition

2 Improved etching uniformity using 8" disc covering over the sample chuck (6/19/2012)

3 Low stress silicon nitride etching using SF6 (8/5/2008)

1. Oxygen plasma etching(cleaning) condition

- The base pressure: ~0.06 Torr

- O2 pressure: 1.4-1.5 Torr, Note: the vacuum indicator on the tool is not accurate.

- RF power: 250 W

2. Improved etching uniformity using 8" disc covering over the sample chuck (6/19/2012)

- Since the exhausting port of the chamber is in the center of sample chuck, the gas flow around the center is much larger than that around periphery of the chuck. As a result, the etching rate is not uniform.

- The etching uniformity can be improved by controlling the gas flow. The following example indicates the improvement of the etching uniformity by suppressing the gas flow to the exhausting port using a 8" disc covering over the whole chuck.

- The detailed report (6/19/2012) is posted in the following:

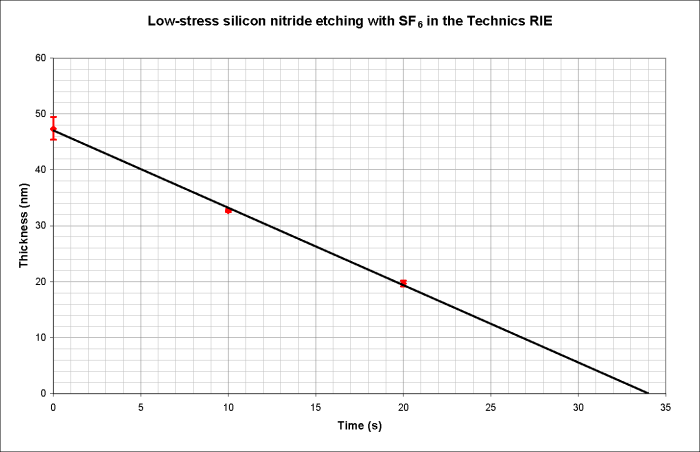

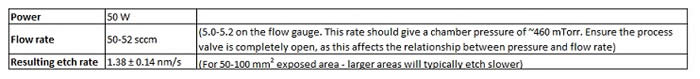

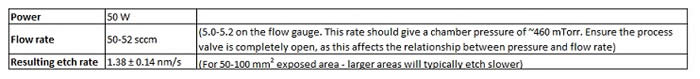

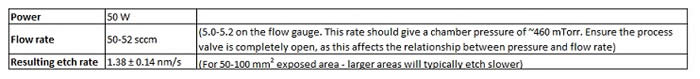

3. Low stress silicon nitride etching using SF6 (8/5/2008)

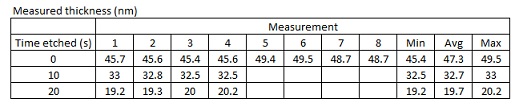

3.1 Calibration details

Carried out on 08/05/2008 by Ken Healy (healyk@sas).

The sample etched was low-stress (200-300 MPa) LPCVD silicon nitride on (100) silicon, deposited at the Cornell CNF. Thicknesses were measured with the Rudolph Ellipsometer.