Updated on 11/2/2015

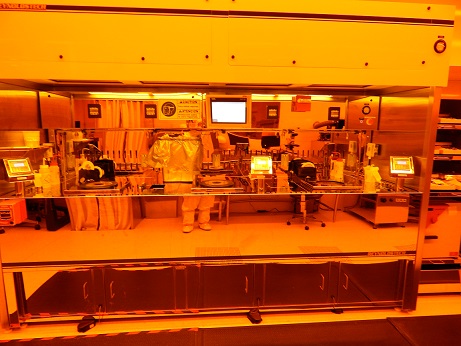

1 Bay 2

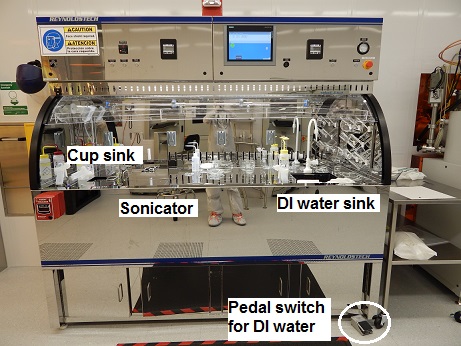

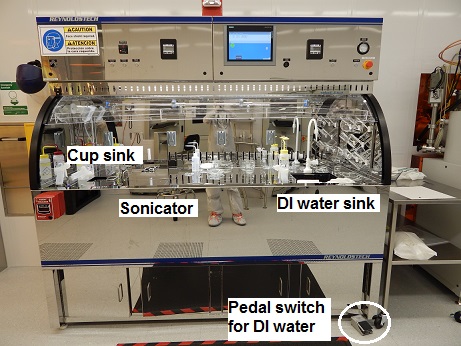

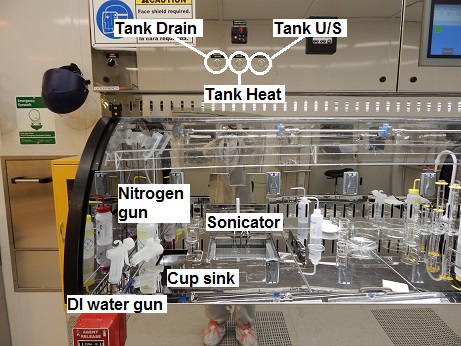

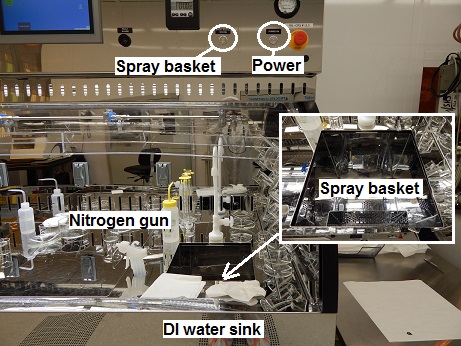

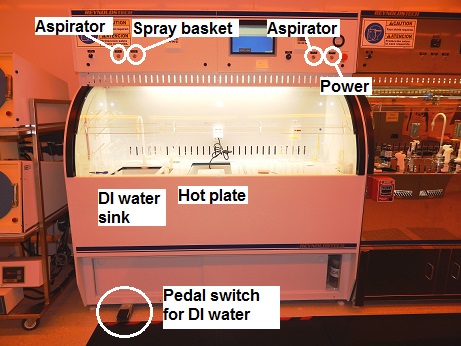

1.1 Strip Bench

1.1.1 Sonicator

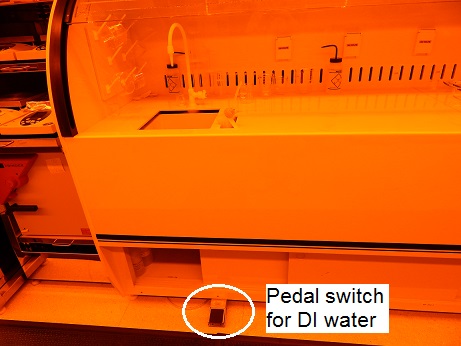

1.1.2 DI water sink

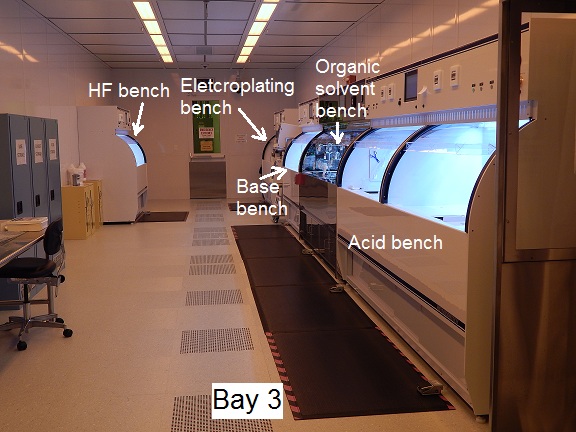

2 Bay 3

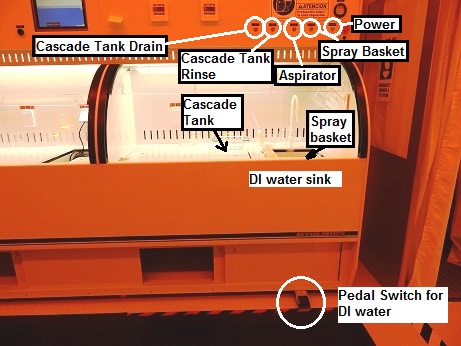

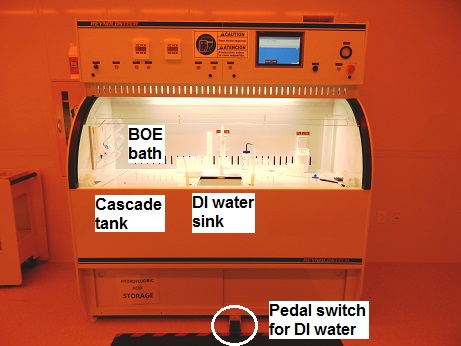

2.1 Acid Bench

2.1.1 Acid Bench 1

2.1.2 Acid Bench 2

2.1.3 Discarding Waste Acid Solution

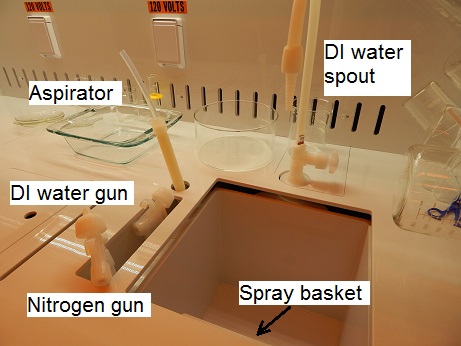

2.2 Base Bench

2.2.1 Discarding Waste Base Solution

2.3 Organic Solvent Bench

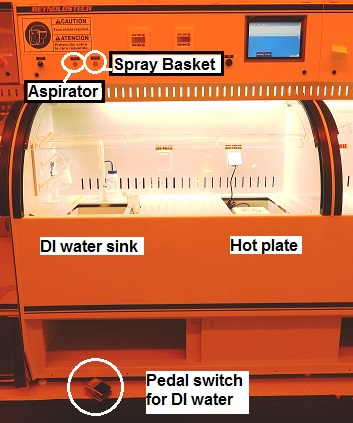

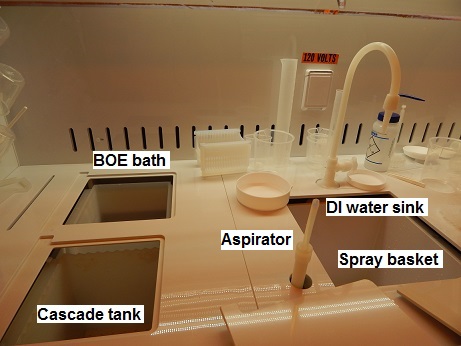

2.4 HF Bench

2.4.1 Discarding Waste HF Solution

2.5 Electroplating Bench

3 Bay 4

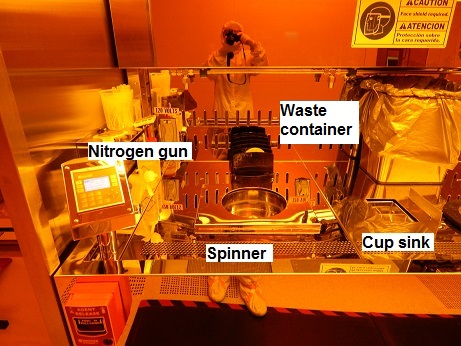

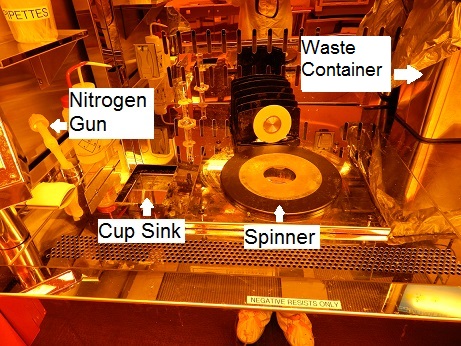

3.1 Spinner Bench and Developing for E-beam Lithography

3.1.1 Develop Sample

3.1.2 Discarding Waste Developing Solution

4 Bay 5

4.1 Spinner Benches for UV Lithography

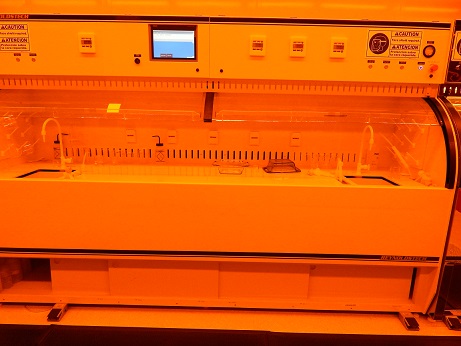

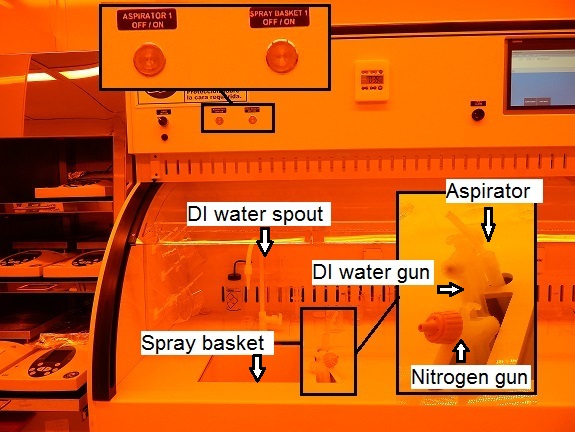

4.2 Develop Bench

4.2.1 Develop Sample

4.2.2 Discarding Waste Developing Solution

4.3 Organic Solvent Bench

5. Soft Lithography Room

5.1 Spinner Bench for Soft Lithography

Note:

Note: To fill the tank with DI water, use the DI water gun.

Note: If the amount of water is reduced beyond the setpoint, the sonicator switch will be interlocked.

Note:

Note:

Note:

Note:

Note:

Note: