Wet Processing

Updated on 8/28/2015

See general info on etch rates of materials in Etch_rates_for_micromachining_processing.

Contents

1 Bay 3

1.1 Overview

1.2 Apron, faceshield, and gloves

2 HF

2.1 Standard Operation Procedure

3 Nanostrip

3.1 Standard Operation Procedure

4 How to clean

4.1 Glassware

4.2 Silicon Wafer

4.3 Glass Wafer

5 Wet Silicon Etch

6 Accessories

6.1 Wet Processing Wafer Chuck

6.2 Alkaline Protective Coating

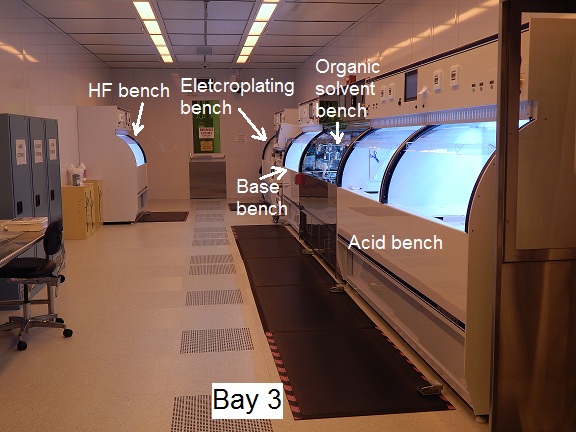

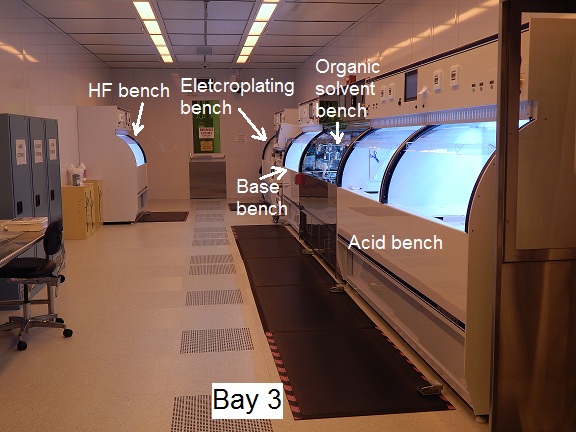

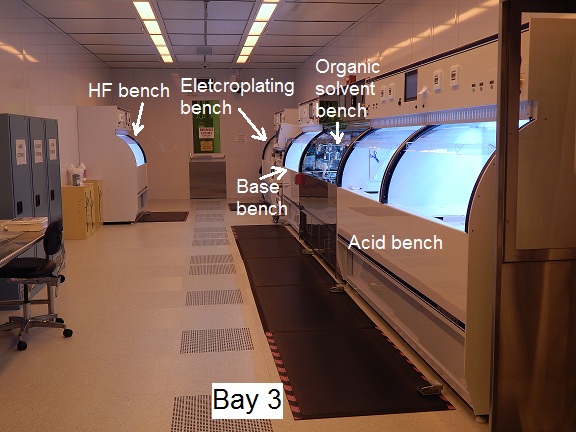

1. Bay 3

1.1 Overview

1.2 Apron, face shield, and gloves

Note:

- You MUST wear an apron, a face shield, and nitrile gloves when you get in Bay 3.

- You need a safety buddy to work in Bay 3 from 7:00 PM to 9:00 AM on Monday-Friday, and all day on Saturday, Sunday, and holiday.

2. HF

3. Nanostrip

4. How to Clean

4.1 Glassware

- General Cleaning

- Ultra-sonicate the glassware with Acetone for 5 min.

- Ultra-sonicate the glassware with isopropyl alcohol (IPA) or methanol for 5 min.

- Thorough Cleaning

- Physical cleaning the glassware using scrubber and detergent as much as possible

- Chemical cleaning the glassware

1. Organic Clean: Immerse the glassware in surfactant for laboratory overnight

2. Inorganic Clean: Immerse the glassware in 3 mol/L HCl solution for 2-3 hours

1. Organic Clean: Immerse the glassware in concentrated sulfuric acid for 2-3 hours to remove organics

4.2 Silicon Wafer

- General Cleaning

- Ultra-sonicate the wafer with Acetone for 5 min.

- Ultra-sonicate the wafer with isopropyl alcohol (IPA) or methanol for 5 min.

- Thorough Cleaning: RCA cleaning

Werner Kern developed the basic procedure in 1965 while working for RCA (Radio Corporation of America) - hence the name.

- Organic Clean: Removal of insoluble organic contaminants with a mixed solution of H2O: H2O2 (30 wt%): NH4OH (28-30 wt%) = 5:1:1 at 80 °C for 10 min.

- Oxide Strip: Removal of a thin silicon dioxide layer where metallic contaminants may accumulated as a result of (1), using a diluted H2O: HF solution.

- Ionic Clean: Removal of ionic and heavy metal atomic contaminants using a mixed solution of H2O: H2O2 (30wt%): HCl (36-38 wt%) = 6:1:1 at 75-80 °C for 10 min.

4.3 Glass Wafer

- Ultra-sonicate the wafer with Acetone for 5 min.

- Ultra-sonicate the wafer with isopropyl alcohol (IPA) or methanol for 5 min.

- Thorough Cleaning

- Removal of insoluble organic contaminants and making the surface smooth with a mixed solution of H2O: H2O2 (30 wt%): NH4OH (28-30 wt%) = 4:1:1 at 80 °C for 30 min.

5. Wet Silicon Etch

It is possible to wet-etch silicon isotropically or anisotropically, using Potassium hydroxide (KOH), Tetramethylammonium hydroxide (TMAH), EDP (an aqueous solution of ethylene diamine and pyrocatechol), or a mixed solution of Hydrofluoric acid (HF), Nitric acid (HNO3), and Acetic acid (CH3COOH). Wet silicon etch is useful to deeply etch or penetrate through a silicon wafer. See the detail of the following references:

References:

- Silicon_etching

- Wet-Chemical_Etching_and_Cleaning_of_Silicon

- Isotropic_Silicon_Etch

- Chemical_etch_of_silicon

6. Accessories

6.2 Alkaline Protective Coating

- See ProTEK B3 Datasheet.

- Spin-coat (1) ProTEK B primer and (2) ProTEK B-25 on the sample surface.

- Remove the films using ProTEK Remover 100 after the process.